Introduction to WPC Wall Panels

In today’s construction and design landscape, WPC wall panels have emerged as a revolutionary alternative to traditional building materials. These innovative panels combine the best qualities of wood and plastic, offering homeowners and contractors a durable, attractive, and sustainable solution for both interior and exterior applications.

What Makes WPC Different?

Unlike conventional wood panels that require constant maintenance or plastic panels that lack aesthetic appeal, WPC wall panels provide:

- The natural appearance of real wood

- The durability of high-grade plastics

- Exceptional resistance to environmental factors

- Low maintenance requirements

The Science Behind WPC Composition

Core Components

WPC panels consist of three primary elements:

- Wood Fibers (40-70%) – Typically from fast-growing species or recycled wood waste

- Thermoplastics (30-60%) – Usually HDPE, PVC, or PP from recycled sources

- Additives (0-5%) – Including UV stabilizers, colorants, and binding agents

Manufacturing Process

The production of WPC panels involves:

- Material Preparation – Wood fibers are dried and ground to precise specifications

- Compounding – Wood and plastic are mixed with additives at high temperatures

- Extrusion – The composite material is shaped into panels through specialized dies

- Finishing – Surface textures and protective coatings are applied

Unmatched Benefits of WPC Wall Panels

1. Superior Durability

WPC panels outperform traditional materials in:

- Impact resistance (withstands up to 3x more force than standard wood)

- Scratch and dent protection

- Structural integrity maintenance over time

2. Weather Resistance

Independent testing shows WPC panels can endure:

- Temperature extremes (-40°F to 176°F)

- 100% humidity conditions

- Continuous UV exposure without fading

3. Eco-Friendly Advantages

Compared to conventional materials, WPC panels:

- Contain 60-80% recycled content

- Reduce deforestation by utilizing wood waste

- Are 100% recyclable at end-of-life

- Lower carbon footprint by 35% over their lifecycle

4. Health and Safety Benefits

WPC panels contribute to healthier indoor environments by:

- Resisting mold and mildew growth

- Emitting zero VOCs (Volatile Organic Compounds)

- Being naturally hypoallergenic

Comprehensive Applications of WPC Panels

Residential Uses

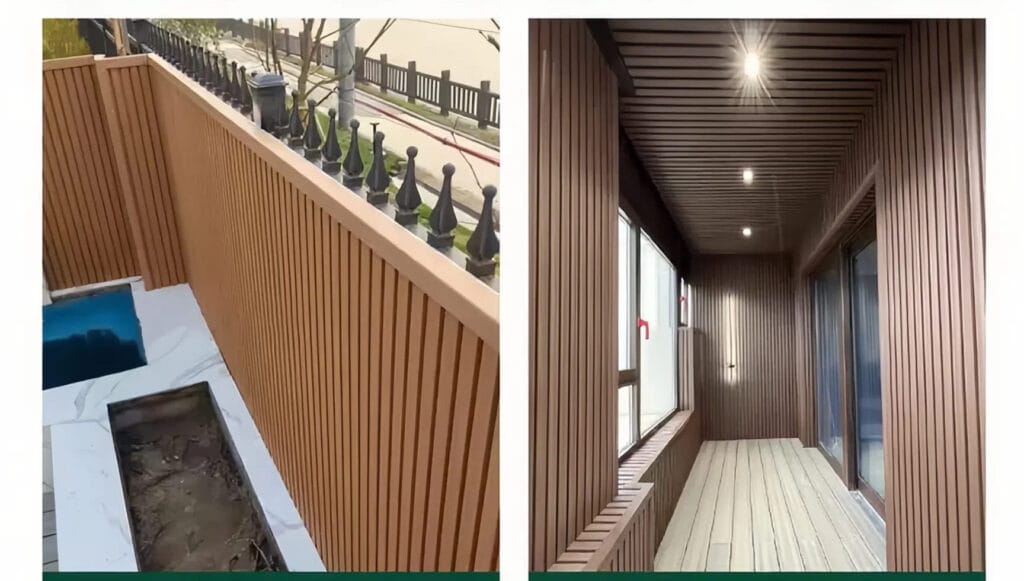

Interior Applications

- Feature walls in living rooms

- Bedroom accent walls

- Kitchen backsplashes

- Bathroom wall coverings

- Basement finishing

Exterior Applications

- House cladding and facades

- Balcony and patio walls

- Poolside enclosures

- Garden feature walls

Commercial Implementations

- Restaurant interior walls

- Hotel lobby accents

- Office partition systems

- Retail store displays

- Healthcare facility walls

How to install WPC Wall Panels

Preparation Steps

- Surface Assessment – Ensure walls are clean, dry, and structurally sound

- Acclimation – Let panels adjust to room temperature for 48 hours

- Layout Planning – Create installation diagrams accounting for:

- Panel orientation

- Pattern matching

- Transition points

Installation Methods

Direct-to-Stud Installation

- Install horizontal furring strips at 16″ centers

- Secure panels using corrosion-resistant fasteners

- Maintain 1/8″ expansion gaps at edges

Adhesive Application

- Apply high-bond construction adhesive in zigzag pattern

- Press panel firmly against substrate

- Use temporary bracing until adhesive cures

Professional Tips

- Use carbide-tipped blades for clean cuts

- Pre-drill holes near panel edges

- Stagger joints for enhanced stability

- Seal edges in high-moisture areas

Maintenance and Care Instructions

Routine Cleaning

- Weekly Dusting – Use microfiber cloth or soft brush

- Monthly Wash – Mild soap solution with soft sponge

- Annual Deep Clean – Specialized WPC cleaner application

Seasonal Maintenance

Spring:

- Inspect for winter damage

- Check fastener tightness

Fall:

- Clear debris from panel grooves

- Apply protective coating if needed

Problem Solving

Stain Removal:

- Food stains: Baking soda paste

- Ink marks: Isopropyl alcohol

- Grease: Degreasing cleaner

Surface Repair:

- Minor scratches: Color-matched filler sticks

- Deeper damage: Panel replacement

Cost Analysis and ROI

Price Comparison

| Material | Cost per sq.ft | Lifespan | Maintenance Cost/Year |

|---|---|---|---|

| Natural Wood | $8-$15 | 10-15 years | $2.50 |

| Vinyl | $3-$7 | 15-20 years | $1.00 |

| WPC | $5-$12 | 25+ years | $0.50 |

Value Proposition

- 5-7 year payback period compared to wood

- 30% lower lifetime costs than traditional materials

- Increased property value from durable, attractive finishes

Environmental Impact Assessment

Sustainability Metrics

- Carbon Sequestration: 2.5 lbs CO2 per sq.ft stored

- Recycled Content: Minimum 60% post-consumer waste

- End-of-Life Options: Fully recyclable or biodegradable

Certifications to Look For

- FSC (Forest Stewardship Council) Certification

- GREENGUARD Gold for indoor air quality

- Cradle to Cradle Certified® products

Frequently Asked Questions

Q: How long do WPC panels last?

A: Properly installed WPC panels typically last 25-30 years with minimal maintenance.

Q: Can WPC panels be painted?

A: While possible, it’s not recommended as the original finish provides optimal protection.

Q: Are WPC panels fire-resistant?

A: WPC has a Class B fire rating, meaning it’s resistant to flame spread but not fireproof.

Q: How do WPC panels handle extreme cold?

A: WPC maintains structural integrity down to -40°F without becoming brittle.

Future Trends in WPC Technology

Emerging Innovations

- Smart WPC Panels – Integrated with temperature regulation

- Self-Cleaning Surfaces – Photocatalytic coatings

- Enhanced Biocomposites – Higher plant-based content

Market Growth Projections

The global WPC market is expected to grow at 11.2% CAGR through 2030, driven by:

- Increased green building regulations

- Rising demand for low-maintenance materials

- Advancements in manufacturing technologies

Why Choose Gladol WPC Wall Panels?

Gladol stands out in the WPC industry by offering:

- Premium Materials: Highest-grade wood fibers and recycled HDPE

- Advanced Manufacturing: Proprietary extrusion technology

- Design Variety: 25+ wood-grain patterns and colors

- Industry-Leading Warranty: 15-year limited warranty

Customer Success Stories

- Residential Case: 35% reduction in maintenance costs for beachfront property

- Commercial Project: 50,000 sq.ft hotel facade completed 2 weeks ahead of schedule

Final Recommendations

For optimal results with WPC wall panels:

- Consult with professionals for large projects

- Order samples to verify color and texture

- Plan for expansion (1/8″ per 10 linear feet)

- Follow manufacturer guidelines for cleaning and care

If you’re looking for the best price on WPC wall panels, feel free to contact us. Gladol is a WPC wall panel factory from China with 15 years of industry experience.